Sewer jetters require high pressure to effectively clear out debris and blockages from pipes. Understanding the ideal pressure for a sewer jetter is crucial for maintaining plumbing systems.

Key Takeaways

- Proper pressure is crucial: Understanding the pressure requirements for sewer jetting is essential for effective cleaning and maintenance.

- Select the right equipment: Determine the appropriate pressure needed for your specific applications to ensure efficient and thorough cleaning.

- Prioritize safety: High-pressure jetting requires proper safety measures to prevent accidents and injuries.

- Regular maintenance is key: To maintain optimal pressure and functionality, sewer jetters need regular maintenance and care.

- Consider all factors when purchasing: When buying a sewer jetter, consider pressure requirements alongside other important factors such as nozzle types and flow rates.

- Benefits of adequate pressure: Adequate pressure in jetting ensures thorough cleaning, blockage removal, and efficient maintenance of sewer systems.

Understanding Sewer Jetting

Understanding the difference between pressure and flow is crucial. Pressure refers to the force of the water as it exits the jetter, while flow rate is about how much water is being expelled.

The importance of high pressure in sewer jetting cannot be overstated. High-pressure water can effectively break down and dislodge stubborn blockages, including tree roots, grease, and mineral build-up within pipes. For instance, a sewer jetter operating at 4000 PSI (pounds per square inch) has enough force to clear out tough clogs compared to lower pressure systems.

Balancing pressure and flow is essential for optimal sewer cleaning results. While high pressure tackles tough obstructions, an adequate flow rate ensures that debris is efficiently flushed away from the pipe. A well-calibrated system strikes this balance perfectly.

Determining Jetter Pressure Needs

Pipe Size Impact

When determining how high pressure does the sewer jetter need, it’s crucial to consider the pipe size. Different pipe diameters require varying jetter pressure for effective cleaning. For instance, smaller pipes may necessitate higher pressure to clear blockages effectively.

Adapting jetter equipment to different pipe diameters is essential for achieving optimal cleaning results. Challenges arise when dealing with varying pipe sizes during sewer cleaning, as each diameter demands a specific level of pressure for efficient blockage removal.

Blockage Types

Understanding different types of sewer blockages is vital in tailoring jetter pressure requirements. By identifying various blockage compositions, such as grease buildup or root intrusion, you can adjust the pressure accordingly to address specific blockage types effectively.

Tailoring jetter pressure based on the composition of the blockage ensures thorough and targeted cleaning. It’s important to comprehend the nature of each type of obstruction, as this knowledge directly influences the effectiveness of your sewer jetting efforts.

Flow Rate Considerations

Evaluating the impact of flow rate on sewer jetting efficiency is crucial when determining pressure needs. Adjusting flow rate based on the nature of the blockage allows you to achieve an optimal flow rate that complements your chosen pressure level for thorough pipe cleaning.

Balancing both flow rate and pressure ensures comprehensive and efficient pipe cleaning while minimizing potential damage caused by excessive force or inadequate water volume.

Selecting the Right Sewer Jetter

GPM and PSI Balance

It’s crucial to understand their relationship. The GPM determines the water flow rate, while the PSI measures the force of that water. For instance, a higher GPM allows for faster cleaning, while increased PSI provides more power to break through tough clogs.

To ensure the right balance for different cleaning tasks, consider a scenario where a high-pressure jetter with low GPM might not effectively clear out large debris but would work well on smaller obstructions. On the other hand, a lower-PSI machine with higher GPM could efficiently flush out larger blockages but may struggle with hardened deposits.

Jetter Nozzle Selection

The importance of selecting an appropriate nozzle cannot be overstated when addressing different cleaning requirements. The nozzle design significantly impacts water pressure and spray pattern. For example, rotary nozzles are ideal for cutting through roots or removing hard scale buildup due to their concentrated stream.

Matching the nozzle type to specific blockage characteristics is essential; penetrating nozzles excel at pushing through dense clogs in pipes without causing damage from excessive pressure. Conversely, flusher nozzles are best suited for flushing loose debris from pipe walls without requiring as much force.

Machine Portability

Considering portability when choosing a sewer jetting machine is vital as portable jetters offer benefits such as accessing confined spaces easily. However, there are trade-offs between power and portability in jetter selection; larger machines provide greater force but can be cumbersome in tight spaces compared to compact models offering less power.

High-Pressure Applications

Residential Cleaning

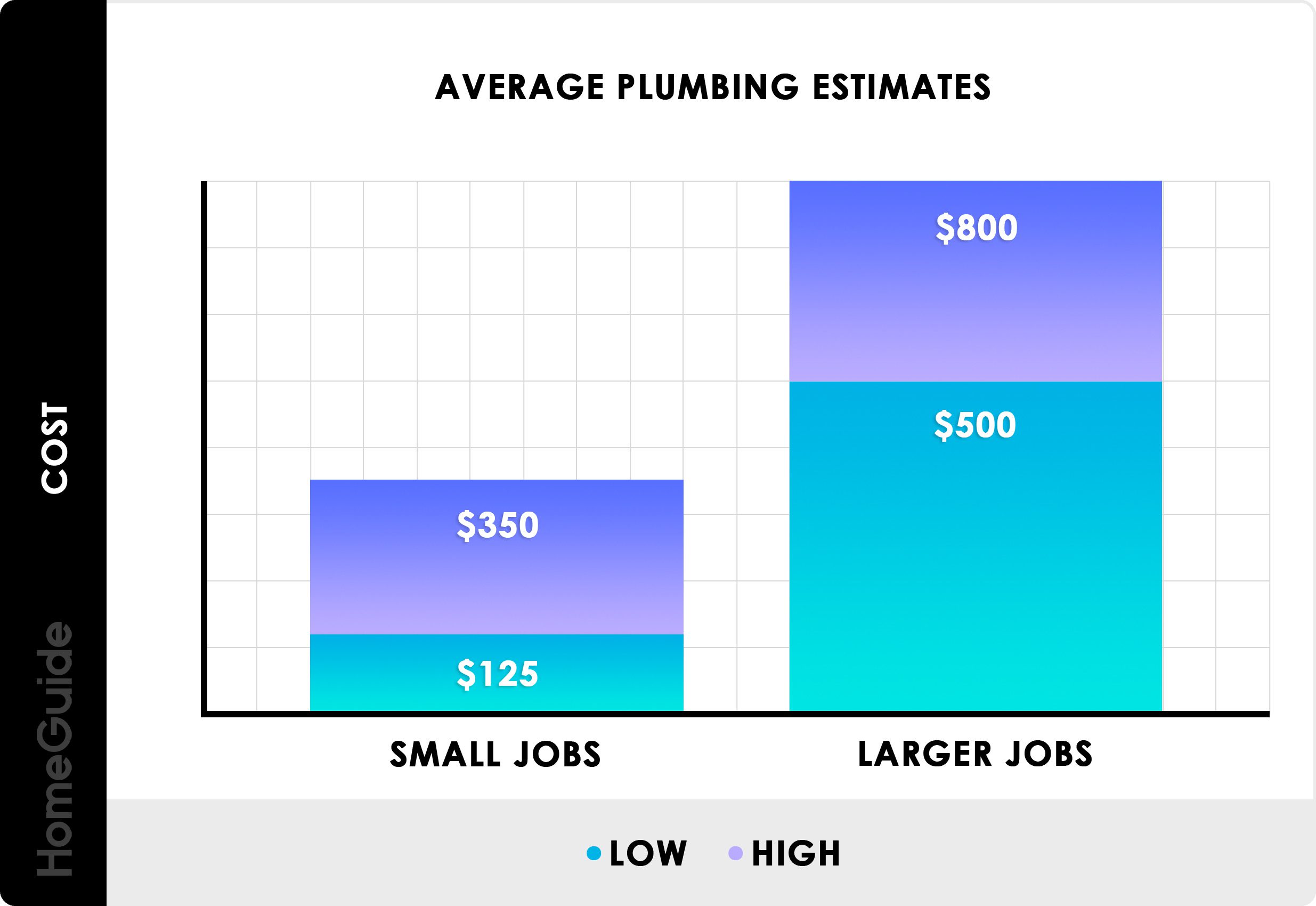

The required pressure for a sewer jetter depends on the specific needs of the household. Tailoring the jetter’s pressure ensures that common residential blockages, such as grease and soap scum build-up, are effectively addressed. By using appropriate pressure levels, minimal disruption to residential plumbing systems can be ensured during cleaning.

For instance:

- A lower pressure setting might be suitable for clearing minor clogs in bathroom drains.

- Higher pressures may be necessary for more stubborn blockages in kitchen or laundry lines.

Commercial Maintenance

In commercial settings, sewer jetters need to adapt their pressure levels to meet maintenance demands efficiently. Handling larger-scale blockages requires increased water pressure, ensuring effective removal of debris and sediments from commercial pipes. This approach minimizes downtime through efficient pipe cleaning, allowing businesses to resume operations promptly.

For example:

- Restaurants and hotels may require high-pressure sewer jetters to clear grease accumulation in their kitchen drainage systems.

- Shopping malls and office buildings might benefit from powerful jetters capable of handling heavy foot traffic-related debris in their restroom facilities.

Industrial Use Cases

Industrial pipe maintenance demands robust equipment with high-pressure capabilities. Evaluating these requirements is crucial when selecting a sewer jetter for industrial use cases. Heavy-duty industrial blockages necessitate powerful sewer jetters with adequate water pressure to ensure thorough cleaning and maintenance of industrial infrastructure.

For instance:

- Manufacturing plants often encounter tough obstructions due to production byproducts; therefore, they require high-pressure sewer jetters designed specifically for industrial applications.

- Refineries dealing with oil-based substances rely on powerful equipment capable of maintaining their intricate piping systems.

Benefits of Adequate Pressure in Jetting

Efficiency Boost

A sewer jetter with the right level of high pressure can significantly increase efficiency. By optimizing water pressure, the equipment maximizes productivity, leading to time and cost savings. For example, when dealing with tough blockages or debris in pipes, higher water pressure ensures quick and effective removal, reducing the overall time required for cleaning.

High-pressure equipment offers numerous benefits in boosting overall efficiency. It allows for faster completion of tasks, minimizes manual labor requirements, and enhances the overall performance of sewer jetting operations.

Thorough Cleaning

Appropriate water pressure is crucial for achieving thorough pipe cleaning. High-pressure water effectively breaks down stubborn deposits within pipes that may be resistant to lower pressures. This ensures that all areas within the piping system are thoroughly cleaned and maintained.

By using high-pressure water during sewer jetting, cleanliness throughout the entire piping system is preserved. This helps prevent future clogs or build-up that could lead to more serious issues over time.

Longevity of Pipes

The use of suitable jetter pressure levels plays a vital role in preserving pipe integrity and longevity. Careful consideration of water pressure helps avoid damage to pipes while still effectively clearing blockages and debris from within them.

Safety in High-Pressure Jetting

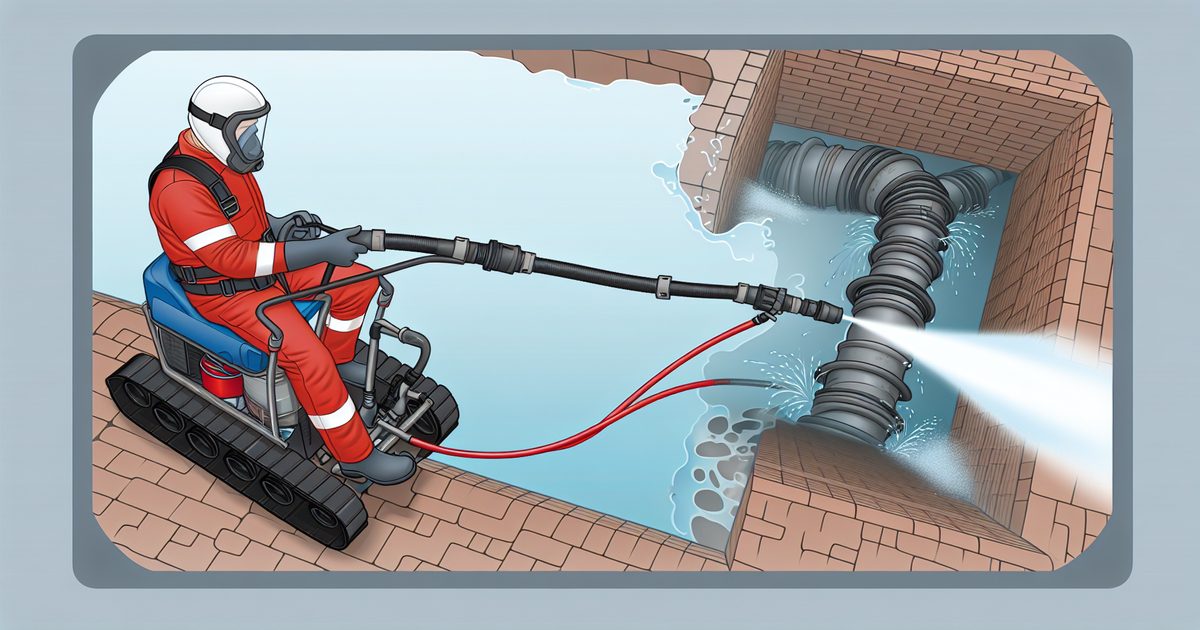

Operator Precautions

When considering how high pressure does the sewer jetter need, it’s crucial to prioritize operator safety. Operators must take necessary precautions when using high-pressure sewer jetters, such as wearing appropriate protective gear and receiving thorough training on equipment operation. Awareness of potential risks associated with high-pressure equipment is essential to prevent accidents and injuries during sewer cleaning tasks.

Maintaining a keen focus on operator safety not only safeguards the individual but also ensures efficient and effective completion of cleaning tasks. By understanding the power of high-pressure water jetting, operators can mitigate risks and handle the equipment responsibly, promoting a safe working environment.

Equipment Handling

Proper handling techniques play a pivotal role in preserving both equipment integrity and operator safety. When operating high-pressure sewer jetting machines, it’s imperative to adhere to careful handling procedures that minimize wear and tear while maximizing longevity and effectiveness. Regular maintenance routines should be implemented to keep the machinery functioning optimally for extended periods.

By prioritizing meticulous equipment handling, operators can significantly reduce the likelihood of malfunctions or breakdowns during operations. This not only enhances overall efficiency but also minimizes downtime due to equipment issues, ensuring seamless completion of sewer cleaning tasks.

Environmental Considerations

Assessing environmental impact is paramount when determining optimal jetter pressure levels for various cleaning applications. Minimizing ecological effects while utilizing high-pressure water for cleaning involves striking a balance between achieving cleanliness goals and upholding environmentally conscious practices in sewer maintenance activities.

Operators should aim to limit excessive water usage while still effectively clearing blockages or debris from sewers, contributing positively towards sustainable environmental stewardship.

Maintenance of Sewer Jetters

Routine Checks

To maintain consistent high-pressure performance of a sewer jetter, it’s crucial to conduct routine checks. This involves inspecting the equipment regularly to detect any potential issues that could affect its pressure output. By incorporating periodic maintenance and inspection, you can ensure reliable operation and prevent unexpected breakdowns during cleaning tasks.

For example, checking for leaks in hoses or fittings can help identify areas where pressure might be lost. Examining the condition of nozzles and valves is essential for maintaining optimal water pressure during operation. These routine checks not only contribute to efficient high-pressure performance but also enhance the overall safety of using sewer jetting equipment.

Troubleshooting Tips

When facing common issues related to high-pressure sewer jetters, troubleshooting becomes essential for optimizing water pressure during cleaning tasks. Diagnosing problems such as reduced pressure or irregular flow requires a systematic approach to identify the root cause and implement effective solutions.

For instance, if there are pressure-related problems, recommended solutions may include inspecting and clearing clogged nozzles or adjusting the engine speed on gas-powered units. Utilizing appropriate techniques for troubleshooting ensures that high-pressure sewer jetters operate at their full capacity without compromising their effectiveness.

Long-Term Care

Sustaining long-term effectiveness of high-pressure sewer jetters relies on proper care and maintenance practices over time. Establishing a comprehensive approach to long-term equipment care involves preserving functionality through regular servicing, lubrication of moving parts, and adherence to manufacturer-recommended maintenance schedules.

Purchasing Considerations for Sewer Jetters

Warranty Importance

When investing in high-pressure sewer jetters, it’s crucial to evaluate the warranty coverage. Comprehensive warranties offer long-term equipment protection, which is beneficial for heavy-duty machinery like sewer jetting machines. Factors to consider regarding warranty options include coverage duration, parts included, and service availability.

A comprehensive warranty can provide peace of mind by protecting your investment from unexpected repairs or replacements. For example, a warranty that covers both the pump and engine of a sewer jetter ensures holistic protection against potential malfunctions.

Shipping Options

Assessing shipping considerations is essential when acquiring high-pressure sewer jetters. Factors influencing shipping logistics for heavy-duty equipment include weight, dimensions, and delivery location. Making informed decisions about shipping methods ensures timely and cost-effective delivery of large-scale machinery.

Some suppliers may offer specialized freight services tailored to heavy-duty equipment transportation needs. These services can include liftgate delivery or inside delivery options specifically designed for transporting bulky items like sewer jetting machines.

Return Policies

Evaluating return policies is crucial when purchasing high-pressure sewer jetters. Factors impacting return options for heavy-duty equipment involve restocking fees, return window duration, and condition requirements upon return. Navigating return processes for large-scale machinery purchases requires thorough understanding of the supplier’s policies.

For instance, some suppliers may impose restocking fees based on the item’s condition upon return or the time elapsed since purchase. Understanding these factors helps in making an informed decision before investing in a high-pressure sewer jetter.

Final Remarks

You’ve now grasped the crucial factors in determining the right pressure for your sewer jetter, ensuring optimal performance and safety. Remember, the key is finding the balance between ample pressure for effective cleaning and avoiding excessive force that could damage pipes. With this knowledge, you can confidently select a sewer jetter that meets your specific needs, whether it’s for residential or commercial applications.

Now that you understand the significance of pressure in sewer jetting, take the next step by evaluating your current equipment or exploring options for a new purchase. Keep in mind the insights shared here to make an informed decision that aligns with your requirements. Your proactive approach to selecting the right sewer jetter will not only enhance efficiency but also contribute to prolonging the lifespan of your plumbing system. Happy jetting!

Frequently Asked Questions

How do I determine the pressure needed for my sewer jetter?

To determine the pressure needed for your sewer jetter, consider factors like pipe material, diameter, and the type of blockage. A higher pressure may be required for tougher clogs or longer pipes.

What are the benefits of adequate pressure in sewer jetting?

Adequate pressure ensures effective removal of stubborn clogs and debris from pipes, leading to improved flow and reduced chances of future blockages. It also helps in maintaining overall system hygiene.

Is high-pressure jetting safe for sewer maintenance?

When used correctly by trained professionals, high-pressure jetting is a safe method for cleaning sewers. However, it’s important to follow safety guidelines and use appropriate protective gear.

How should I maintain my sewer jetter to ensure optimal performance?

Regular maintenance such as cleaning nozzles, inspecting hoses for wear and tear, checking engine oil levels, and ensuring proper water filtration will help keep your sewer jetter performing at its best.

What should I consider when purchasing a sewer jetter?

Consider factors such as the power source (gasoline or electric), flow rate, nozzle types available, hose length, portability options, warranty coverage, and customer reviews before making a purchase decision.